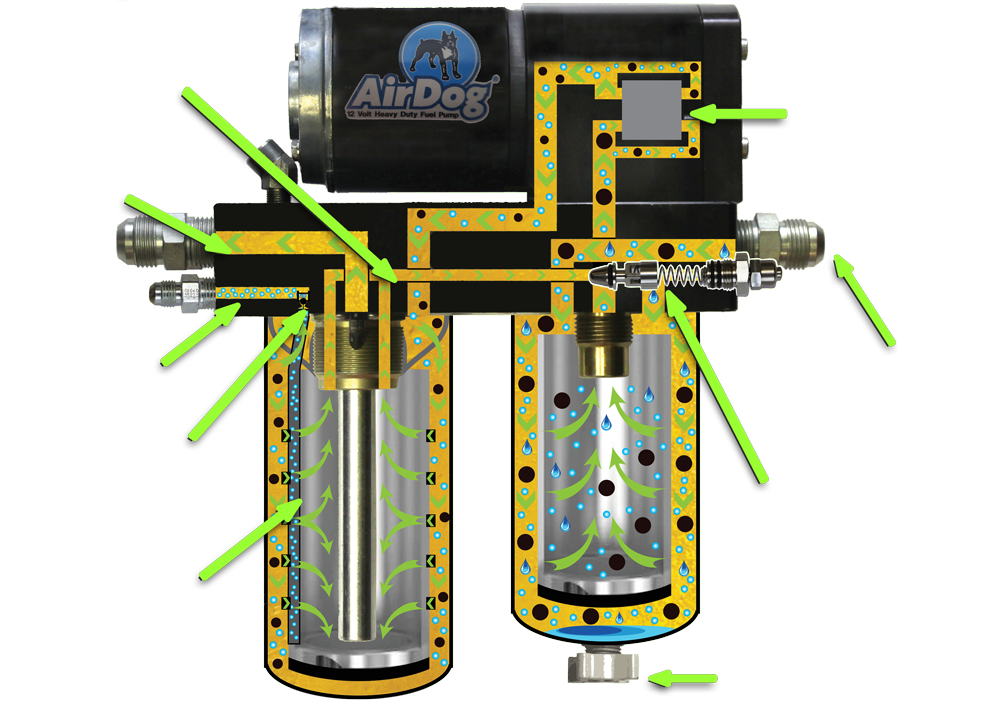

Diesel fuel entrains air, primarily introduced by fuel sloshing in fuel tanks, and by vapor caused by negative pressure and/or restrictions in the fuel supply lines and filters between the fuel tank and fuel injection system. When this entrained air makes its way into the fuel injection system, the results are a loss of throttle response, reduction in power, reduced fuel economy, rough idle, increased noxious emissions, and increased wear on fuel injectors. The primary purpose of the AirDog® diesel fuel systems is to remove the entrained air from diesel fuel, before the air can enter the injection system, thereby restoring optimal diesel fuel systems performance, sending a supply of pure fuel, with no air or other contaminants, to the engine under positive pressure.

Hover over icons above for more information.

The installation of the PureFlow™ systems results in smoother engine idle, improved throttle response and power throughout the engine RPM range, improved fuel economy, prolonged lifespan of fuel injectors, and reduced NOx emissions.

By simply optimizing the engine’s fuel system to perform as designed, AirDog® diesel fuel systems will reduce the costs of fuel system maintenance and repairs, as well as provide a fuel cost savings, for a wide range of diesel engine-powered vehicles: